|

|

|

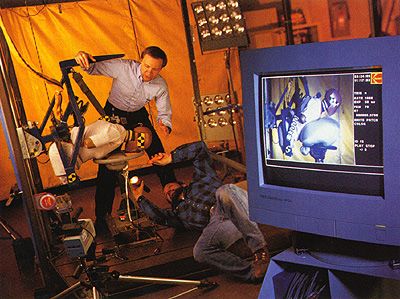

Engineers Mike Wolanin (top) and Les Noblett set up test to assess force exerted when an air bag opens into the neck of a driver who has been leaning far forward over the steering wheel.

|

It may become a G.I. "The military is developing a new pilot trainer, and they need dummies in order to design a cockpit that fits the largest male pilot and also the smallest female," says First Technology vice president Thomas Gutwald. There is also "Lifeman," a dummy designed to get shot so researchers can gauge the wound's impact. Our military buys dummies to test helicopters. Gutwald shows a video of two dummies riding in a five-ton Army truck at Fort A. P. Hill in Virginia. Beneath the truck a land mine is detonated. Once the flame and smoke clear, the seats-and their dummy occupants-remain in place and untouched by shrapnel. The new floor armor and wheel-well deflectors seem to be working.

Meanwhile, dummies also are at work in the civilian world. The Federal Aviation Administration uses crash-test dummies to evaluate airliner seats. And one First Technology dummy is an eye glass-testing head. "It wears glasses, and you shoot balls at it," says Gordon Morgan.

Still, with about 20 million car crashes per year in the United States alone, automotive testing remains the most promising career for dummies Many tests are to make sure that new cars meet federal standards. For those measurements to he accurate, each dummy's sensors must be precisely calibrated. That means the dummies must regularly undergo nasty physicals, including boppings in the chest with a 51.5-pound pendulum. Their knees get smashed with federally specified weights. They also have their heads dropped 14 inches to smack onto a table. "The head hits with about 2,000 pounds of pressure on the forehead," says Joe Balser.

All that is just to make sure the dummies' sensors and physical responses are right. The actual testing can be even more fiendish. In one lab at the Milford Proving Grounds a giant bungee-cord slingshot shoots a pair of dummy knees into an instrument panel. "Or you can put just a head in an impact device and hit it at any angle you like," says Tom Terry benevolently.

A Society for the Prevention of Cruelty to Dummies would be steamed. But it's torture in good causes. For instance, in the Out-of-Position Occupant Testing Laboratory at the Milford Proving Grounds, engineer Michael Wolanin is trying to improve air bags. In a crash, riders sitting slumped forward on their seats can be too close to an air bag when it unfurls. Wolanin is trying to redesign the air bags to protect such out-of-position riders. He points out that to be effective, bags must unfold rapidly-almost explosively. And they must be firm enough to restrain an occupant whose body weight is increased to 60 times normal by the crash forces. "We like to use the 5th Percentile Female because a smaller person is more vulnerable," says Wolanin

He is testing a new air bag-already available in some GM cars-that detects when the driver is slumped against the wheel. Instead of unfurling through the air bag compartment's main doors, the bag unfurls through alternate side doors, so that it will not explode directly against the driver's chest, possibly crushing it. To perfect the system, Wolanin's dummies are taking a lot of hits. Electronically, they tell how bad it hurts. "The dummy has told us it's very important how we fold the bag," Wolanin says. "We've developed a new way of folding the bag so that it can shoot out the alternate doors, and the dummies are testing the various fold patterns."

Designers also are working on an air bag that unfurls

[ Previous ] Page: 1 2 3 4 5 6 7 [ Next Page ]

|